Oil-Free Dry Screw Compressors

Oil-Free Dry Screw Compressors

Oil-free rotary compressors indeed offer several benefits in terms of sustainability, reliability, and performance, while also minimizing the total cost of ownership.

Reduced Environmental Impact

As the name suggests, oil-free compressors eliminate the need for lubricating oil in the compression process. This reduces the risk of oil contamination in the air and surrounding environment.

Compliance with Environmental Regulations

Oil-free compressors are often preferred in applications where strict environmental regulations are in place, as they help prevent the release of oil into the air.

Durable Construction

Oil-free compressors are often built with robust materials and construction, allowing them to withstand challenging environmental conditions.

Versatility

These compressors are designed to perform in a variety of environments, including harsh conditions, making them suitable for a range of industrial applications.

Reliability

Without the need for oil lubrication, the maintenance requirements are generally lower compared to oil-lubricated compressors. This can result in increased reliability and less downtime.

Oil-free compressors provide a cleaner compressed air stream, reducing the chances of damage to pneumatic equipment and ensuring consistent performance.

Performance

Oil-free compressors deliver high-quality compressed air without the risk of oil contamination. This is crucial in applications where clean and oil-free air is a requirement, such as in the pharmaceutical and food industries.

These compressors are designed for efficiency, providing a reliable source of compressed air for various industrial applications.

Total Cost of Ownership (TCO)

While the initial cost of oil-free compressors may be higher, the lower maintenance requirements and reduced energy consumption often contribute to lower operating costs over the life of the compressor.

The absence of oil in the compression process can contribute to longer equipment life, reducing the need for frequent replacements.

APPLICATIONS

Automotive

Oil-free dry screw compressors in the automotive industry ensure clean and reliable compressed air, vital for painting, pneumatic tools, and other precision manufacturing processes, reducing maintenance costs and enhancing product quality.

Food & Beverage

In the food and beverage industry, oil-free dry screw compressors provide clean compressed air, which is essential for food processing, packaging, and bottling. They also reduce maintenance downtime and contamination hazards, protecting product integrity and strict quality standards.

Pharmaceuticals

In the pharmaceutical sector, oil-free dry screw compressors provide sterile compressed air, which is essential for medication manufacture, packaging, and quality assurance. They also reduce the danger of contamination and production downtime while preserving product purity and compliance with stringent regulatory requirements.

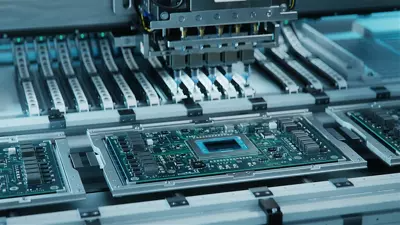

Electronics

Oil-free dry screw compressors in the electronics industry provide clean and dry compressed air, essential for semiconductor manufacturing, circuit board assembly, and precision instrument calibration, ensuring optimal production efficiency and product reliability while reducing the risk of contamination and maintenance costs.

Chemical

In the chemical industry, oil-free dry screw compressors provide contaminant-free compressed air, which is essential for polymer synthesis, chemical processing, and packaging. They also minimize maintenance and downtime costs and ensure product purity, operational safety, and compliance with strict industry regulations.

Oil-Free Dry Screw Compressors

Oil-free rotary compressors indeed offer several benefits in terms of sustainability, reliability, and performance, while also minimizing the total cost of ownership.

Request A Quote