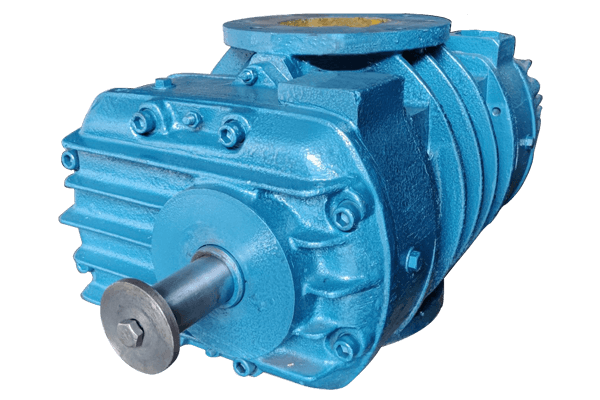

What is a Vacuum Booster?

A vacuum booster, also called a mechanical booster pump, helps vacuum systems work better by making them pump faster and more efficiently. It uses positive displacement mechanisms like Roots blowers, which have rotating lobes to move air or gas through the system. This lets the vacuum system reach lower pressures and handle more gas. Mechanical vacuum boosters are important for applications that need quick evacuation and deep vacuum levels. They reduce the work the main vacuum pump has to do, making it last longer and improving the whole system's reliability. They're also made to last in tough industrial conditions.

Features and Specifiactions of Vacuum Booster

Features

Specification

Spare Parts Used in Vacuum Booster

Bearing

Fasteners

Gaskets

Lob rotors

Seal

RR Enterprice Serves Comprehensive Services for Vacuum Booster

- Our expert technicians keep your air compressor running smoothly. Regular maintenance plans prevent breakdowns and extend lifespan. Need repairs fast? We fix all types of compressors, 24/7 emergencies included!

- Starting a new project? We ensure proper installation for optimal performance. Plus, we test your compressed air quality for top efficiency.

- Protect your compressor with extended service hours and warranties from R R Enterprise.

- Contact us today to discuss your service needs!

Applications of Vacuum Booster

Enhances vacuum levels for distillation, drying, and evaporation processes in chemical and pharmaceutical production, where precise vacuum control is critical for product quality and yield.

Used for vacuum distillation, vapor recovery, and vacuum filtration applications in petrochemical processing facilities to separate and purify various hydrocarbon products.

Provides high vacuum levels for degassing, encapsulation, and vacuum metallization processes in semiconductor manufacturing and other electronics manufacturing operations.

Assists in achieving high vacuum levels required for heat treatment processes such as annealing, brazing, and sintering in vacuum furnace applications.

Utilized for freeze-drying, vacuum packaging, and deaeration processes in the food industry to preserve food products, remove moisture, and maintain product quality and freshness.