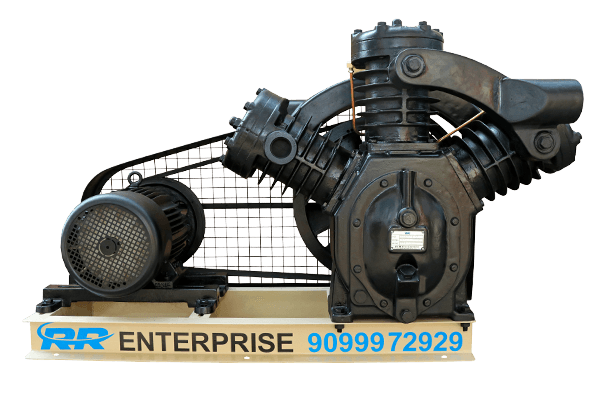

What is a Reciprocating Dry Vacuum Pump?

A reciprocating dry vacuum pump is a type of vacuum pump that produces a vacuum without using any operating fluids such as oil or water, making it an environmentally friendly choice. It works with a piston mechanism similar to that found in an internal combustion engine, in which a piston rotates back and forth inside a cylinder to generate suction. This design ensures that the vacuum created is free of any potential contamination from lubricants or sealants. The absence of working fluids also results in lower maintenance and operating costs. Overall, reciprocating dry vacuum pumps are extremely efficient, long-lasting, and appropriate for a wide range of applications requiring a clean and dependable vacuum source.

Features and Specifiactions of Reciprocating Dry Vacuum Pump

Features

Specification

Spare Parts Used in Reciprocating Dry Vacuum Pump

Bearing

Cylinder Liner

CrankShaft

Piston ring

Pump gaskets

RR Enterprice Serves Comprehensive Services for Reciprocating Dry Vacuum Pump

- Our expert technicians keep your air compressor running smoothly. Regular maintenance plans prevent breakdowns and extend lifespan. Need repairs fast? We fix all types of compressors, 24/7 emergencies included!

- Starting a new project? We ensure proper installation for optimal performance. Plus, we test your compressed air quality for top efficiency.

- Protect your compressor with extended service hours and warranties from R R Enterprise.

- Contact us today to discuss your service needs!

Applications of Reciprocating Dry Vacuum Pump

Used for aeration and agitation of wastewater in treatment plants to promote biological processes and facilitate the breakdown of organic matter.

Handles corrosive and toxic gases in chemical processing plants, where a clean and oil-free vacuum source is required for distillation, drying, and chemical reactions.

Used for vacuum distillation, vacuum drying of pharmaceutical products, and packaging applications where maintaining a sterile environment is essential for product integrity and safety.

Provides vacuum for various manufacturing processes in the electronics industry, including semiconductor manufacturing, vacuum coating, and vacuum packaging of electronic components.

Utilized in scientific laboratories for vacuum filtration, evaporation, freeze-drying, and other research and analytical applications requiring precise vacuum control.

Used for vacuum sealing and packaging processes in the food industry to extend shelf life, prevent spoilage, and maintain product freshness and quality.