Overview

If we understand it simply, Air Compressors generate high pressure by compressing surrounding atmospheric air to a limited area than its original form. This application is almost used in every industry like Automotive, Chemical, Pharmaceutical, Painting, Manufacturing, and Construction.

In this modern world, along with Electricity, Water and Gas Air Compressors are the fourth most used utility because of their irreplaceable feature of powering various applications from households to large-scale industries.

Compressed air is the invisible force behind a vast array of processes, from powering assembly lines for automobiles to operating delicate paint booths and even life-saving medical equipment. But just like any heavy-duty machine, air compressors require proper maintenance and repair to function efficiently and avoid costly downtime. Neglecting preventive maintenance can lead to a major breakdown, costing you thousands for repair and loss in production time.

Types of Air Compressors

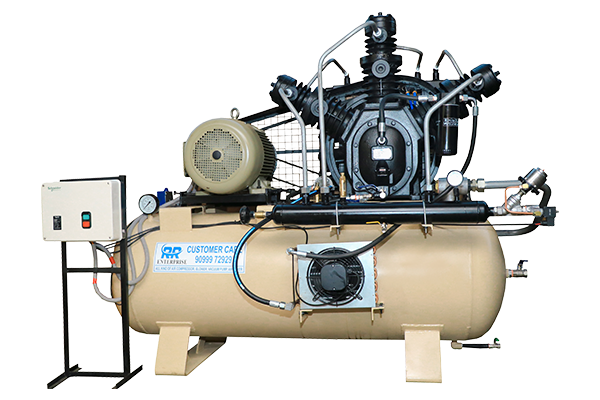

Reciprocating Air Compressors:

These work very similarly to a car engine. A piston moves back and forth within a cylinder, drawing in air on the downstroke and compressing it on the upstroke. Reciprocating compressors are known for their reliability and are well-suited for smaller to medium-sized applications in workshops and garages. They are also generally more affordable than their rotary counterparts.

Rotary Screw Air Compressors:

These employ a set of intermeshing screws within a housing to compress air continuously. Rotary screw compressors offer several advantages, including smoother operation, higher efficiency, and the ability to deliver a constant flow of compressed air. This makes them ideal for larger industrial applications with demanding production requirements.

Importance of Air Compressor Preventive Maintenance

Regular air compressor maintenance is an investment that pays you off in the long run. The following points describe the main advantages:

Reduced Downtime: The last and most important concern for any business owner is that Air Compressor breakdown should not affect the production line. Proactively addressing minor issues through preventive maintenance can prevent unexpected breakdowns that can cost you valuable time and money. Prior problem identification will help you schedule timely repairs, decrease breakdowns, and keep your productions operating smoothly.

Extended Lifespan: Just like any other machine, an air compressor experiences wear and tear, as it is used in business operations. Regular maintenance helps reduce this wear and tear, extending the lifespan of your equipment. This leads to significant cost savings, as you won't have to replace your air compressor prematurely due to disregard. Think of preventive maintenance as an investment in the longevity of your equipment.

Optimized Performance: A well-maintained air compressor operates efficiently, delivering the optimal air pressure and flow according to your specific needs. This ensures that your pneumatic tools and equipment function at their peak performance, leading to better quality output and increased production efficiency.

Lower Energy Costs: An air compressor that is clogged with dirt, has leaking valves, or uses old, worn-out lubricants will consume more energy to achieve the same level of output. Regular maintenance helps identify and resolve these issues, ensuring your air compressor operates efficiently and consumes less energy. Proper and regular maintenance reduces the air compressor's energy consumption by up to 10%, which means it will lower your electricity bills and positively impact your environmental footprint.

By prioritizing preventive maintenance, you're not just protecting your equipment; you're also safeguarding the entire operation. It's a proactive approach that ensures your air compressor maintains its reliability, driving production and keeping your business running smoothly.

Conclusion: Air compressors are indispensable across industries, powering essential processes from automotive assembly lines to delicate medical equipment. Reciprocating and rotary screw compressors each serve distinct functions but there is a need for regular maintenance to ensure efficiency and longevity of both Air compressors.

Preventive maintenance is the keystone of operational success, offering a wealth of benefits. By minimizing downtime, extending equipment lifespan, optimizing performance, and reducing energy costs, proactive upkeep not only preserves machinery but also supports operational resilience.

At the center, this guide contains the strategic importance of preventive maintenance, advocating for foresight and carefulness to maintain operational excellence. Industries prioritizing maintenance ensures reliability, smooth operations, and sustained efficiency.

FAQs

1. What is an air compressor, and what does it do?

An air compressor takes in surrounding air, compresses it to a higher pressure, and stores it in a tank. This compressed air drives various pneumatic tools and equipment used in industries like automotive, construction, and manufacturing.

2. Why is air compressor maintenance important?

Regular maintenance helps prevent unexpected breakdowns, extends the lifespan of your air compressor, optimizes its performance for peak efficiency, and lowers energy costs. It's a beneficial approach that safeguards your entire operation and keeps your business running smoothly.

3. How often should I perform preventive maintenance on my air compressor?

The frequency depends on the type, size, and usage of your air compressor. Generally, manufacturers recommend monthly or quarterly inspections, with oil changes and filter replacements at specified intervals.

4. What are some basic air compressor maintenance tasks I can perform myself?

You can visually inspect your air compressor for leaks, loose connections, or signs of wear and tear. Additionally, draining condensate (water buildup in the tank) and replacing air intake filters are tasks you can manage.

5. When should I call a professional for air compressor maintenance?

For complex tasks like oil changes, replacing internal components, or troubleshooting complex issues, it's best to call a qualified technician. They have the expertise and tools to ensure proper maintenance and avoid any potential damage.

6. Where can I find a recommended maintenance schedule for my air compressor?

Your air compressor's owner's manual will have a specific maintenance schedule with recommended intervals for oil changes, filter replacements, and inspections.

7. What spare parts should I keep in stock for my air compressor?

It's wise to have commonly replaced parts like air filters, condensate drain valves, and any parts specific to your model readily available to minimize downtime during maintenance.

8. What safety precautions should I take when working on my air compressor?

Always follow lockout/tagout procedures to ensure the compressor is off and depressurized before performing any maintenance tasks. Wear appropriate eye protection and gloves when working with the compressor.

Content Summary

Introduction

Types of Air compressors

- Reciprocating Air Compressors

- Rotary Screw Air Compressors

Importance of Air Compressor Preventive Maintenance

- Reduced Downtime

- Extended Lifespan

- Optimized Performance

- Lower Energy Costs

Conclusion

FAQs